Welcome to Cagon Transmission, a leading provider of turnkey transmission system solutions.

We specialize in marine gearboxes, equipment, and spare parts, offering comprehensive marine propulsion systems that include:

Propellers (CPP, FPP, Tunnel Thrusters, Azimuth Thrusters)

Nozzles, Stern Tubes, Seals, and Shafting

Gearboxes, High-Flexibility Couplings, and Remote Control Systems

Our solutions serve a wide range of vessels, including transport ships, offshore vessels, tugs, research vessels, dredgers, fishing boats, and special-purpose ships.

We are positioned as one of the foremost marine power system suppliers in the Chinese market

Our technical team comprises veterans from the Advanced Gearbox Plant, bringing over 20 years of hands-on experience in marine power equipment and a proven track record in designing and developing multiple propulsion systems.

Our products have been extensively exported to Southeast Asia, Africa, Europe, and beyond

After years of steady development and accumulation, Cagon Transmission Technology has transformed into a comprehensive enterprise with superior strength, achieving deep integration and extension of the industrial chain. The company has gathered a group of elite R&D teams, relying on cutting-edge technology and innovative concepts to carry out product research and development; equipped with professional design forces, accurately matching users' personalized needs, and carving application design solutions; the spare parts supply system is complete, responding to customers' emergency needs efficiently, and ensuring that ship operations are "uninterrupted"; the processing and production links strictly abide by international standards, introduce high-end technology and intelligent equipment, and consolidate the foundation of product quality; the ship repair team is experienced, whether it is routine maintenance or emergency repair, it can be solved in a timely and proper manner; the technical support team is "online" 24 hours a day, and can go to the front line at any time to answer questions; the shipbuilding equipment supporting business is constantly improving, adapting to different ship types and construction standards; the marine engineering construction team is not afraid of complex working conditions and harsh challenges, and has repeatedly created high-quality projects.

The company's current products and services are diverse and sophisticated, and its core business segments are full of professionalism: ship propulsion systems integrate advanced power technologies to optimize ship navigation efficiency and control performance; ship gearboxes adhere to precision manufacturing processes to ensure stable and efficient power transmission; ship propellers are deeply polished through aerodynamics and fluid mechanics to help ships break through the waves; ship bearings are made of strictly selected materials and are well made to reduce operating noise and wear; the ship's external fire protection system complies with international fire protection regulations and responds quickly at critical moments to protect the safety of ships and personnel; paint products are environmentally friendly and corrosion-resistant, providing "sturdy protective clothing" for marine equipment; ship maintenance and after-sales services are meticulous, providing all-round escort for the entire life cycle of ship operations.

In addition to focusing on the shipbuilding field, the company also expands its business horizontally with its profound transmission technology accumulation. Various intelligent equipment, logistics transmission components, and agricultural machinery transmission devices have emerged, accurately adapting to complex working conditions of farming operations and improving agricultural production efficiency; automobile transfer cases have excellent performance and adapt to multiple road conditions and driving scenarios; industrial transmission transfer cases meet the high-intensity operation requirements of industrial assembly lines to ensure smooth production processes; precision reducers have leading accuracy and stable operation, enabling the upgrading of high-end manufacturing industries. Adhering to ingenuity and excellence, Hangzhou Cagon Transmission Technology Co., Ltd. will continue to lead the industry development trend in the future and contribute outstanding scientific and technological strength to more fields.

Hangzhou Advance Gearbox Co., LTD., was founded in 1960. Advance is located on the south bank of Qiantang River in Hangzhou. It covers an area of 568,000 square meters and has nearly 1,700 employees, holding and actually controlling 17 subsidiaries, 4 shareholding subsidiaries. “Top 100”, China’s Top 500 Competitive Enterprises of Large Enterprise Groups, and the first batch of national manufacturing single champion demonstration enterprises.

Our Products includes the following:

Marine Transmission

Marine Diesel Engine

Marine/Ship Propellers

Marine/Ship Gear Box

Marine Fire-Fighting Pumps

High Precision Reducer

Boat Engine & Transmission Repairs

Ship Power System Modifications

Solutions for Marine Propulsion Systems

Transmission Device for Agricultural Machinery

Transfer Case (For Automobiles)

Transfer Case for Industrial Transmission

Product use:

Cargo Ship, Container ships, Bulk Carriers, Tanker Vessels, Reefer Vessels, Offshore Vessels, Passenger Vessels, Naval Ships,, Fishing Vessels, Research Vessels

Grain - harvesting machinery, corn - harvesting machinery, balers, knotters, film - wrapping machines, paddy - field sprayers, orchard sprayers, etc. Trucks, off - road vehicles, lorries, construction vehicles. Engineering and industrial fields.

We have passed the GB/T19001 quality system, measurement system, national military standard certification and weapons and equipment production license. We have also passed the "factory approval" of China Classification Society and strict product certification of multinational classification societies such as GL, ABS, NK, KR, CCS, LROS, BV, etc.

Box processing:

■ Patented appearance, beautiful and compact;

■ Precision casting of resin sand metal mold to ensure strength and no leakage;

■ One-time clamping and processing in the machining center, using imported CNC machining center to ensure machining accuracy;

■ Double-process professional cleaning and phosphating equipment, cleaning (removing iron chips), and rust (corrosion) prevention.

Gear production line:

■ Gears (axles) use preheating treatment process

■ Use high-quality low-carbon alloy steel for carburizing and quenching to ensure strength

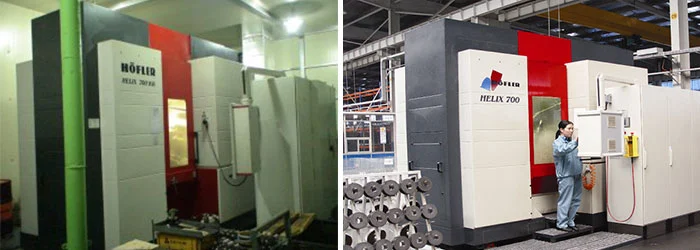

■ Use turning center, CNC high-speed gear hobbing machine, CNC forming gear grinding machine for processing to ensure accuracy

■ Gears use proprietary shaping and noise reduction technology

■ Use cleaning and phosphating line for cleaning and corrosion protection

Heat treatment processing:

■ Pre-heat treatment process is used to ensure the stability of material structure;

■ Fully enclosed heat treatment multi-purpose furnace is used to ensure hardness and strength and effectively control deformation;

■ Strong shot peening technology is used to increase stress and effectively improve the bending strength of tooth root by more than 20%

Assembly line:

■ Station-type flexible assembly line;

■ Circular chain spray drying line;

■ CNC double meshing instrument assembly full inspection;

■ 100% online product operation inspection

The products are sold to the navy and other shipowners in France, the Netherlands, Greece, Turkey, Brazil, Morocco, Myanmar, Indonesia, Singapore, Malaysia, Pakistan, Cambodia, the Middle East and other regions and countries.

◆Ship type: scientific research ship

◆Ship length: 37 meters

◆Ship width: 7.8 meters

◆Designed draft: 2.0 meters

◆Designed speed: 12 knots

◆Lubrication method: Oil lubrication

◆Propulsion method: Single engine single propeller adjustable propeller

◆Ship owner: Zhejiang Ocean University

◆Shipyard: Qingdao Geshida Shipbuilding Co., Ltd.

Ship type features: This ship is a scientific research ship. The propeller blades are specially designed according to the different speeds required by different scientific research modes, and advanced HF series propeller hubs are used. For this project, we provide a complete set of ship propulsion systems including main engine, gearbox, shaft generator, high elastic coupling, shaft system and analysis, stern tube, adjustable propeller, remote control system, hydraulic system, etc.

Hull information:

◆Ship type: fishing boat

◆Ship length: 53.5 meters

◆Ship width: 8 meters

◆Designed draft: 3 meters

◆Designed speed: 15.5 knots

◆Lubrication method: Oil lubrication

◆Propulsion method: Dual engines and dual adjustable propellers

◆Owner: Chinese Army

◆Shipyard: CRRC Taizhou No. 7816 Factory

The 53-meter fishing boat is quite special and has the following characteristics: 1. It has a high speed; 2. It has good maneuverability; 3. It has strong wind resistance; 4. It has a long endurance